【Features】

【Features】

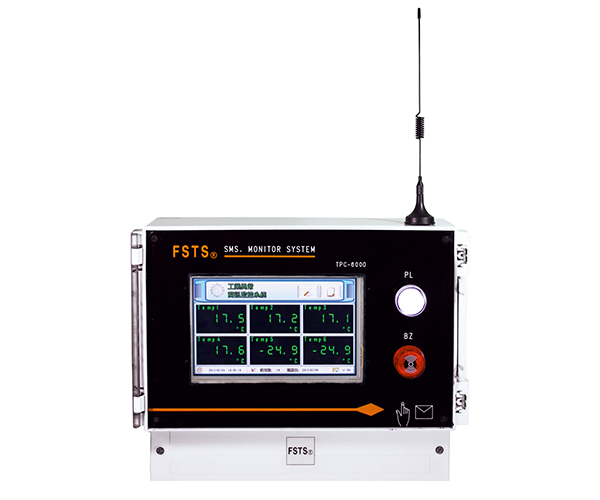

| Power Supply | 110/220 VAC |

| Temperature Of Working Environment | -20℃~70℃ |

| Temperature And Humidity For Storage | -20℃~70℃ 0~85%RH |

| Controlled Output | 5 Points. HH-H-L-LL 4 Sections |

| One Set Common-Point Alarm | 1A/125VAC (With Reset Function) |

| Communication Setting | RS485 Mobus RTU |

| Waterproof Class | IP65 Made Of ABS |

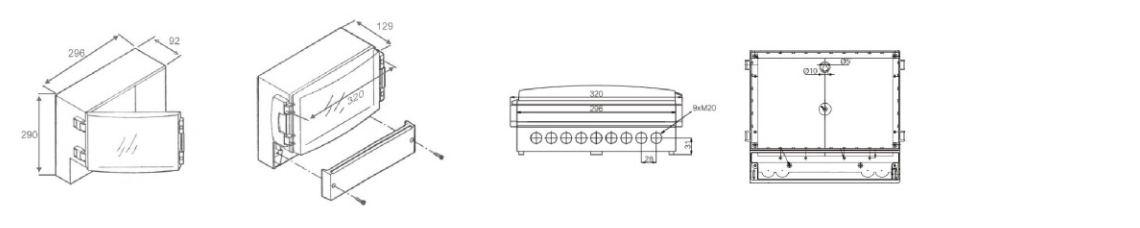

| Product Dimensions | 320 x 290 x 129 (WxHxD) |

| Input Signal | 4-20mA or PT100Ω or T/C℃ |

| Input Terminals | 6pt |

| Display | 7” Color Touch Panel (800x480) |

| Precision | ±0.1% F.S |

| Power Consumption | 8W~10W(MAX) |

| Sampling Time | 10次/秒 |

| Product Weight | 2.15kg |

| Installation Method | Wall-Mounted |

► Functions

► Occasions